Why Air Filtration Is Important for Machines and Power Plants

Clean air is one of the most valuable—and most underestimated—resources in industrial environments. Whether operating gas turbines, compressors, generators, HVAC systems, or other heavy-duty machinery, the quality of the air entering a system directly affects performance, safety, and long-term reliability. In power plants, even small fluctuations in air quality can translate into significant drops in efficiency or costly equipment failures.

At , we design advanced air filtration systems engineered to protect machinery from harsh industrial contaminants. This guide explains why air filtration matters, how it affects machine performance, and what industries can do to safeguard their equipment.

The Role of Air Filtration in Industrial Machinery

Air filtration ensures that the air entering machinery is clean, stable, and free from dangerous contaminants. Industrial environments contain high levels of dust, sand, soot, moisture, and chemical vapors—all of which can cause severe damage if not filtered out.

For beginners learning about filtration, the best starting point is understanding What Air Filters Do and how they work, because filtration begins long before the air reaches the machine itself. Air filters remove harmful particles that can erode components, disrupt combustion, and reduce system efficiency.

Why Air Filtration Matters in Power Plants

Power plants depend heavily on consistent airflow to generate energy. Gas turbines, for example, ingest hundreds of kilograms of air per second, making them extremely sensitive to airborne contaminants. Even small dust particles can accumulate on compressor blades, reducing aerodynamic efficiency and increasing fuel consumption.

Filtration plays several vital roles in power plant operations:

✔ Protecting Critical Components

Clean air helps prevent blade erosion, fouling, corrosion, and overheating.

✔ Improving Combustion Quality

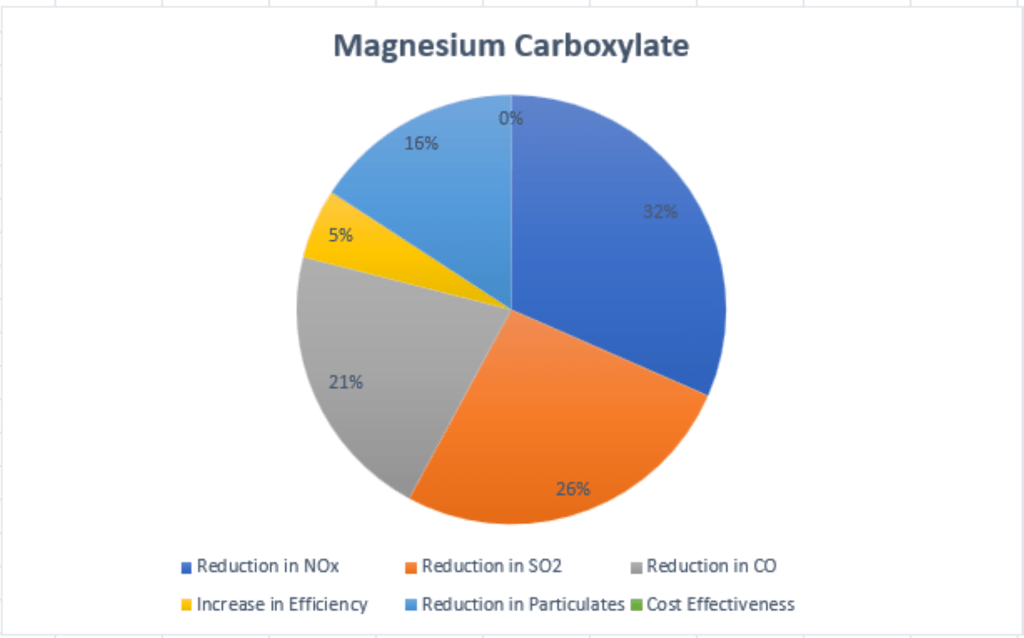

Cleaner air enables complete and stable combustion, resulting in higher output and lower emissions.

✔ Reducing Fuel Costs

Efficient air systems allow turbines and engines to burn fuel more effectively.

✔ Supporting Environmental Compliance

Cleaner combustion lowers harmful emissions such as NOx and CO.

✔ Extending Machine Lifespan

Reduced contamination means fewer breakdowns and longer service life.

A modern power plant cannot operate efficiently without strong air filtration practices.

Industrial Risks When Air Filtration Fails

Many facilities only discover the importance of air filtration after experiencing equipment issues. Dirty or clogged air filters create multiple operational problems, as explored in Common Problems Caused by Dirty or Clogged Air Filters.

Some of the biggest risks include:

1. Pressure Drop and Reduced Efficiency

When filters clog, airflow drops, and machines must work harder to draw in air. This leads to higher fuel consumption and declining performance.

2. Compressor Fouling and Blade Erosion

Fine particles that bypass poor filtration systems accumulate on compressor blades, reducing airflow efficiency and requiring costly cleaning cycles.

3. Overheating and Load Instability

Restricted airflow can cause temperature imbalances, leading to overheating and potential shutdowns.

4. Higher Maintenance Costs

Machines exposed to unfiltered air experience more frequent breakdowns, unplanned outages, and costly repairs.

5. Reduced Output in Power Plants

Even a small decline in turbine efficiency can lead to significant revenue loss, especially in large-scale operations.

These risks highlight why air filtration is not optional—it is an essential part of machine care and plant safety.

Different Types of Air Filters Used in Industry

Not all environments face the same air quality challenges, which is why industries use a variety of filtration technologies. Learning about the Different Types of Air Filters Used in Power Plants and Industry helps operators choose the right system for their operating conditions.

Some major filter categories include:

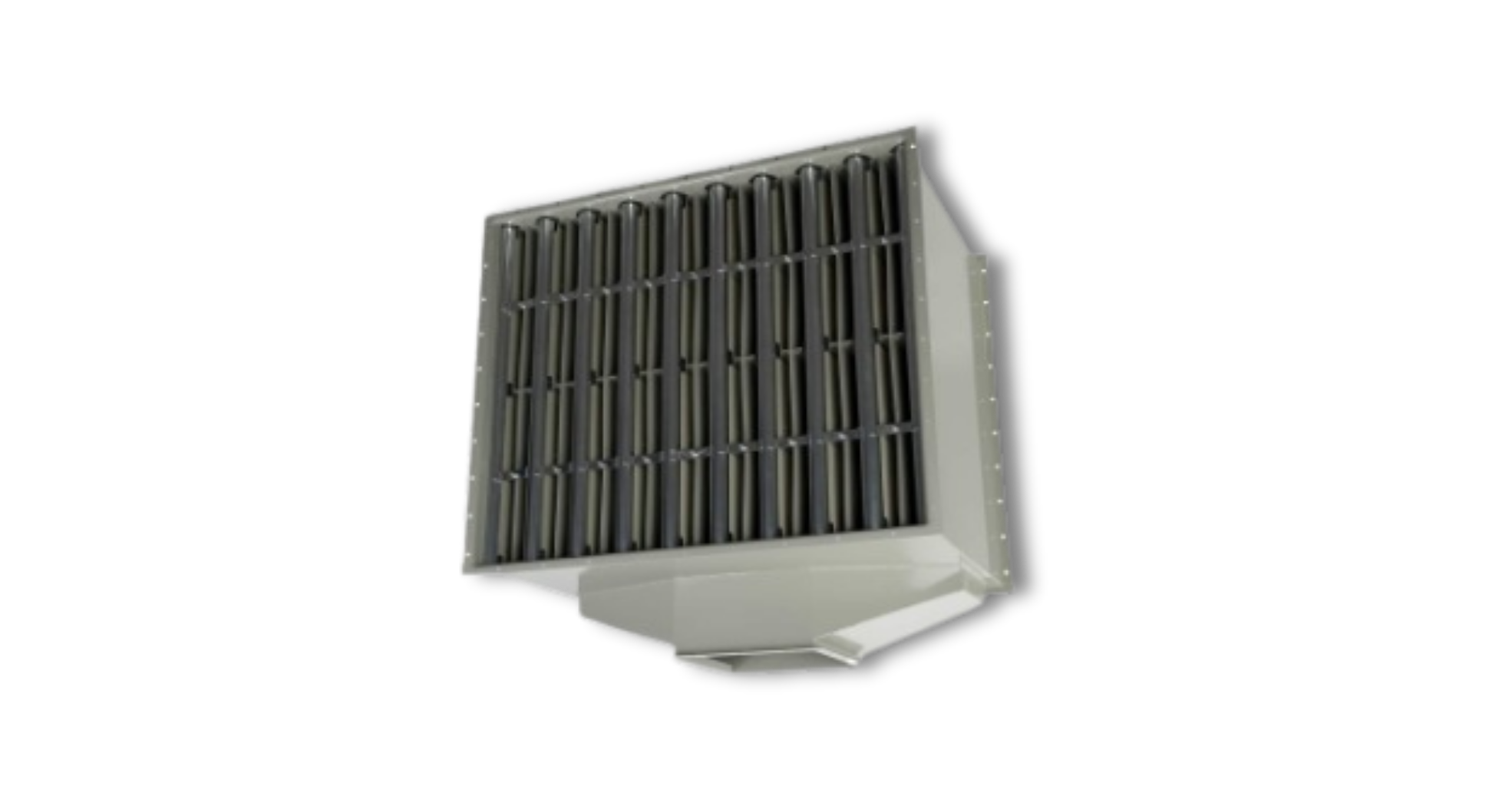

✔ Pre-Filters

Capture large dust and debris to protect downstream finer filters.

✔ EPA & HEPA Filters

Remove extremely fine particles to prevent compressor fouling and performance loss.

✔ Self-Cleaning / Inertial Filters

Ideal for dusty, coastal, or polluted regions where filters must automatically clean themselves.

✔ Carbon Filters

Remove corrosive gases, chemical vapors, and odors.

✔ High-Temperature Filters

Used in industrial systems where air temperatures exceed standard filter limits.

Selecting the right filter type is essential to maximizing equipment efficiency and longevity. ATTS Inc offers engineered filtration solutions for gas turbines, compressors, HVAC systems, and high-dust industrial environments.

How Air Filtration Improves Overall Efficiency

Strong air filtration doesn’t just protect machinery—it directly improves productivity and operational efficiency.

- Higher power output

Clean air allows turbines and engines to operate at optimal airflow levels. - Lower operating expenses

Reduced fuel consumption, fewer breakdowns, and extended maintenance intervals save money in the long term. - More stable machine performance

Consistent airflow means smoother operation, less vibration, and fewer shutdowns. - Improved environmental performance

Reduced contaminant load leads to cleaner combustion and fewer emissions.

By investing in high-quality air filtration, industries can reduce risk and improve energy efficiency across all operations.

FAQs

- Why is air filtration critical for gas turbines and power plants?

Because turbines rely on massive airflow, any contaminants in the air can cause fouling, erosion, overheating, and reduced power output. - What type of air filter works best for harsh environments?

EPA filters, including fine EPA filters, are commonly used in harsh environments due to their balance of efficiency and airflow. - How do I know which air filter is right for my facility?

Filter choice depends on environment, air quality, temperature, and machine type. ATTS Inc can recommend the best filtration solution based on real operating conditions. - Does better filtration improve machine efficiency?

Yes. Clean air improves combustion, reduces fuel use, and helps machines operate at optimal performance. - What industries rely on advanced air filtration?

Power plants, refineries, petrochemical plants, manufacturing facilities, and any industry using turbines or heavy machinery.

Boost in Fuel Efficiency

Boost in Fuel Efficiency